Daily Maintenance and Care Methods for Heating Mats

The core of daily maintenance and upkeep of heating seats is to protect the heating element, maintain electrical safety, and extend material life. Targeted measures should be taken according to their different usage scenarios and material characteristics, while avoiding operations that may damage the product. The following are detailed maintenance methods by dimension:

1、 Universal basic maintenance (applicable to all types of heating seats)

This type of operation is a prerequisite for ensuring the safe operation of the floor heating seat and needs to be performed before and after each use or regularly.

Check before use

- Electrical safety inspection: Before each power on, check whether the power cord is damaged, whether the plug is loose, and whether there is blackening or oxidation at the wiring. If the above problems exist, stop using immediately and contact after-sales. It is strictly prohibited to disassemble and repair on your own.

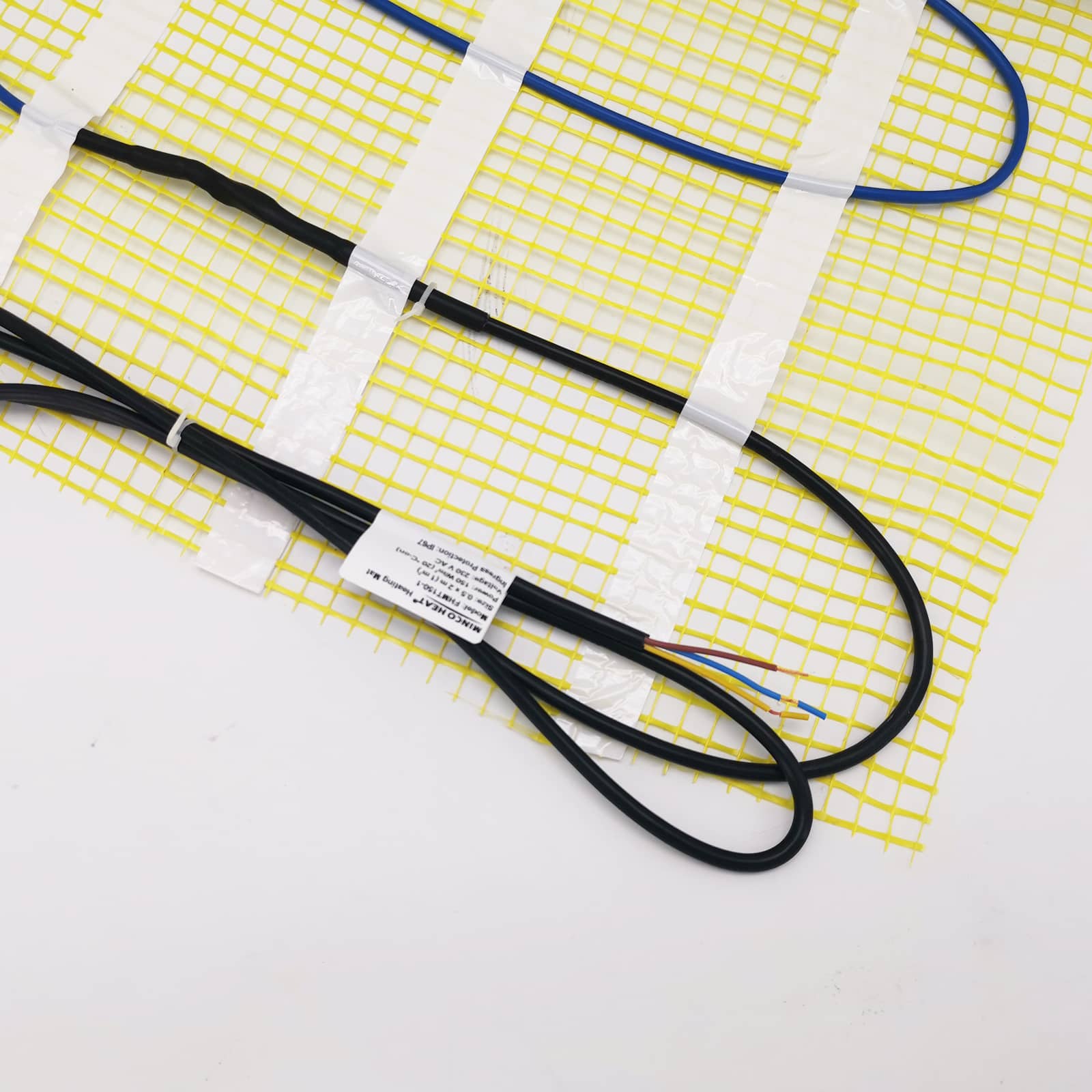

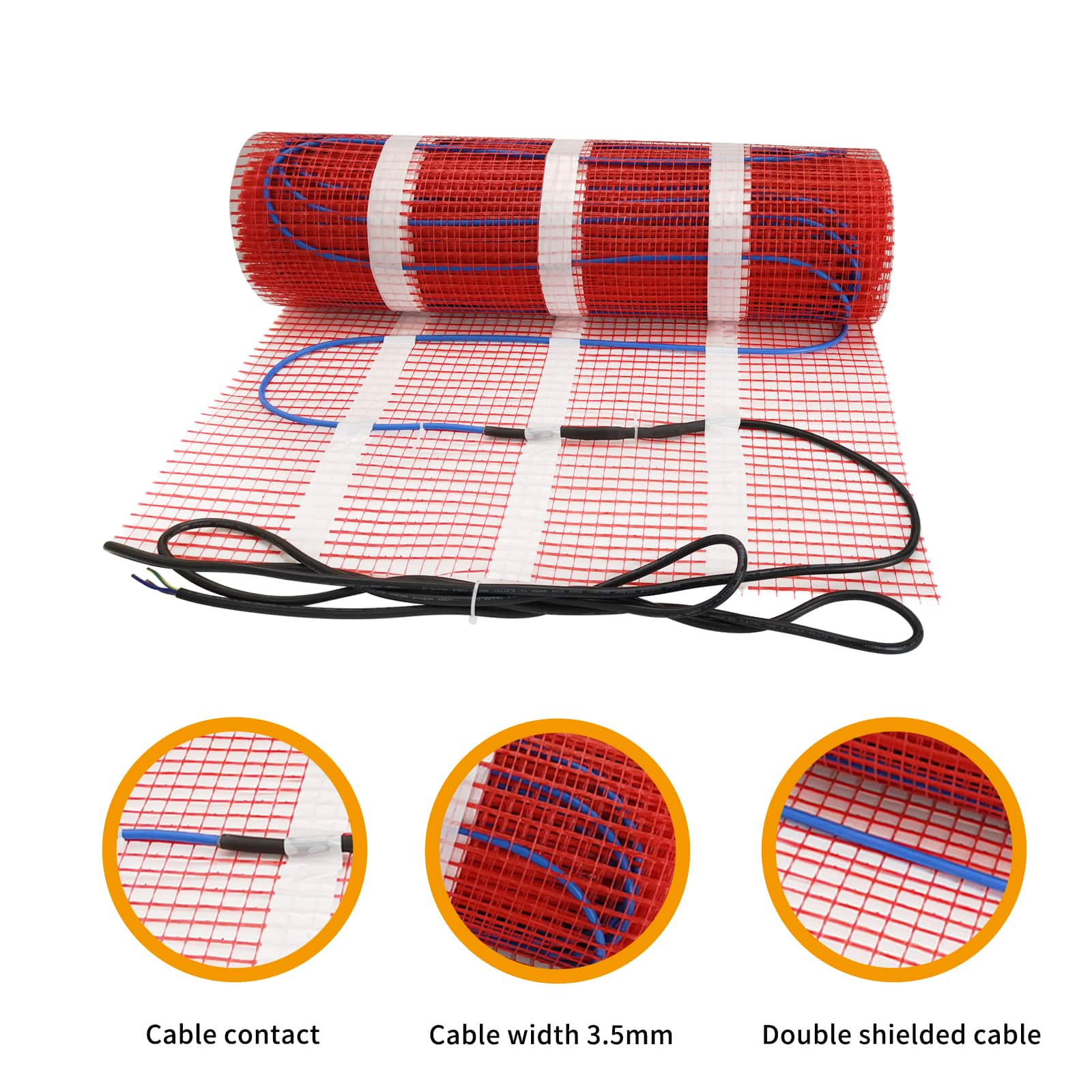

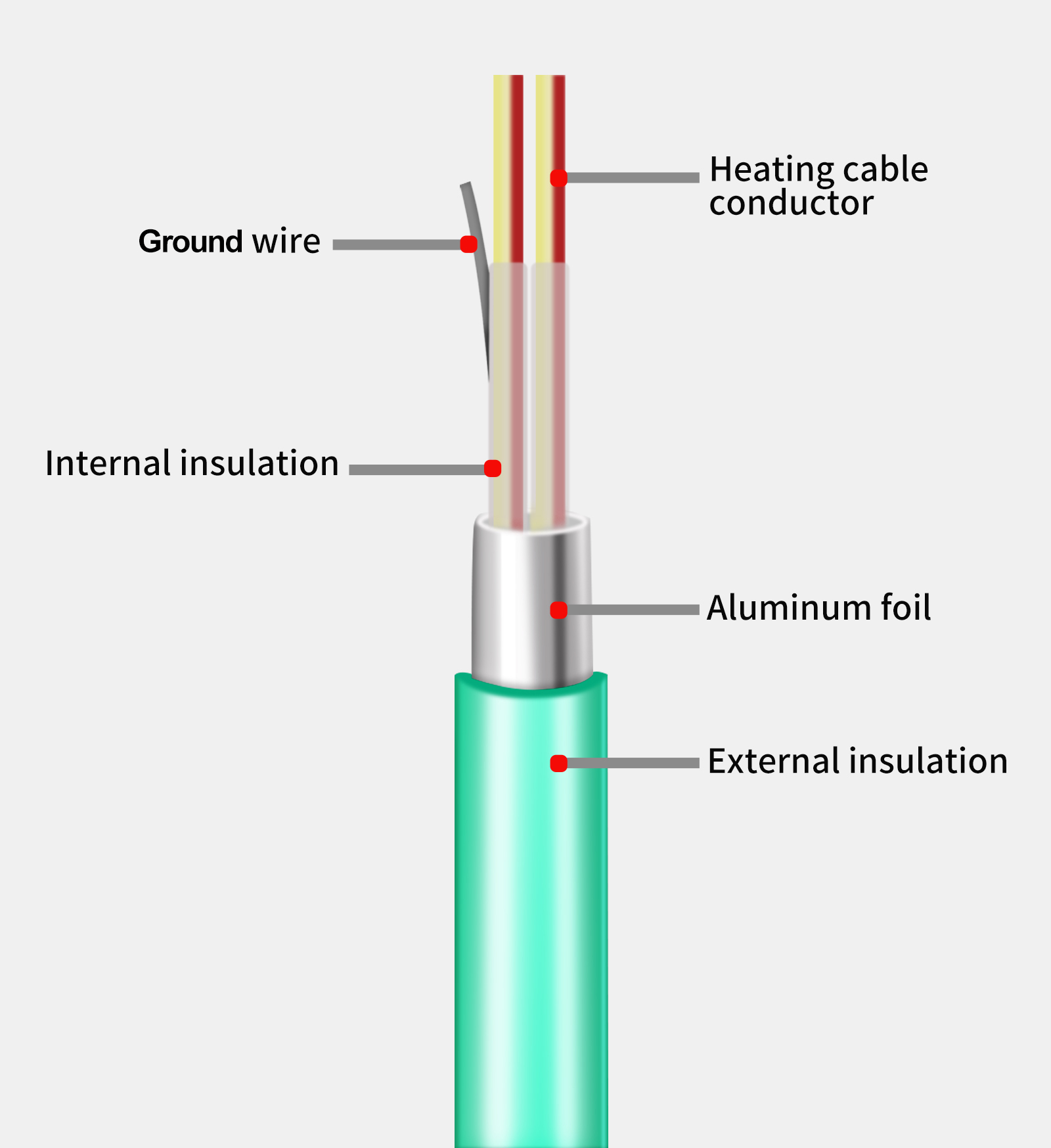

- Appearance inspection: Observe whether there are scratches, bulges, and accumulated stains on the surface of the heating seat. If the surface is damaged, waterproof sealing treatment should be carried out first (special insulation waterproof tape can be applied for household use, and the outer sheath needs to be replaced for industrial use) to prevent moisture and short circuit of the internal heating element.

Protection during use

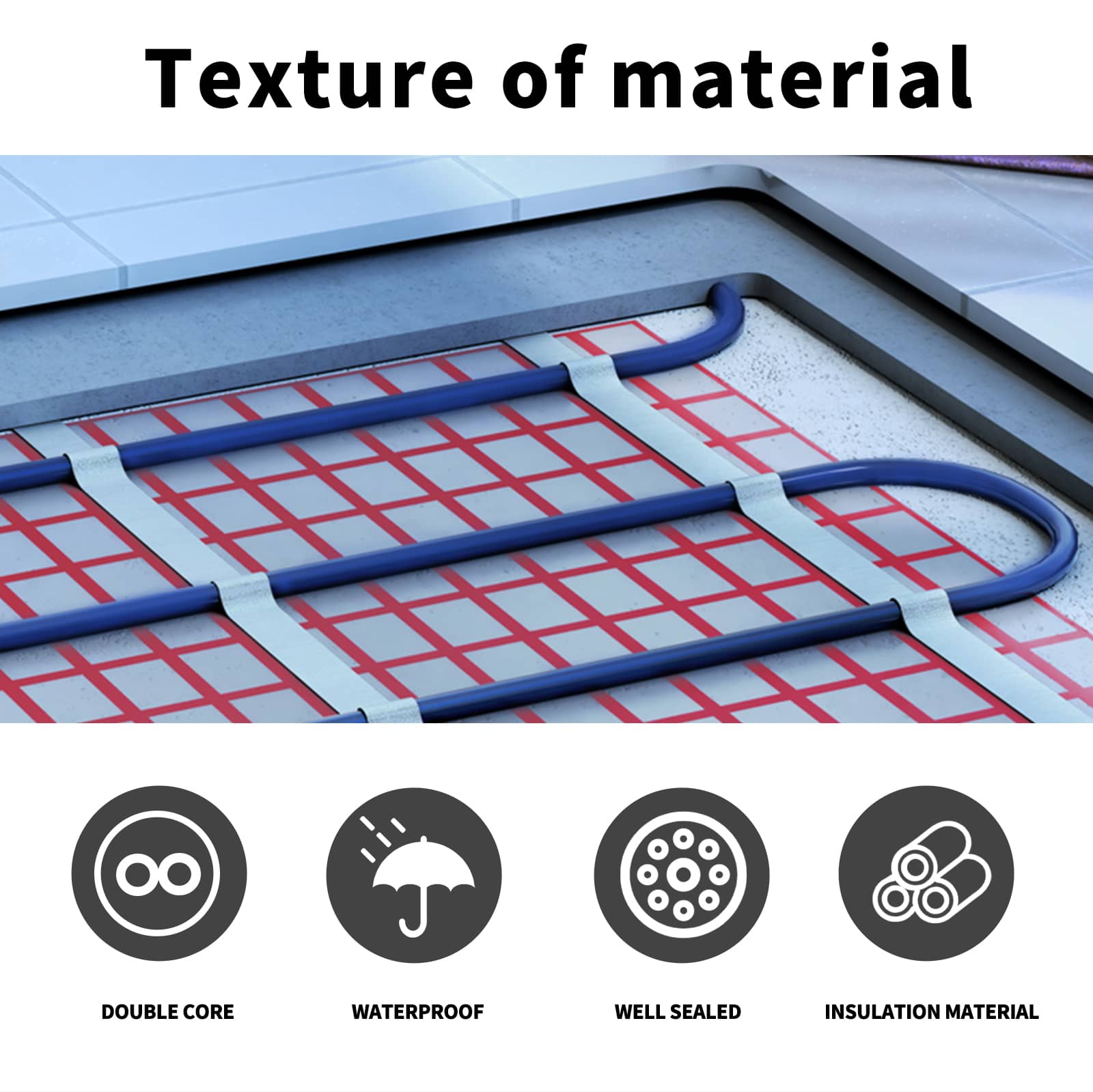

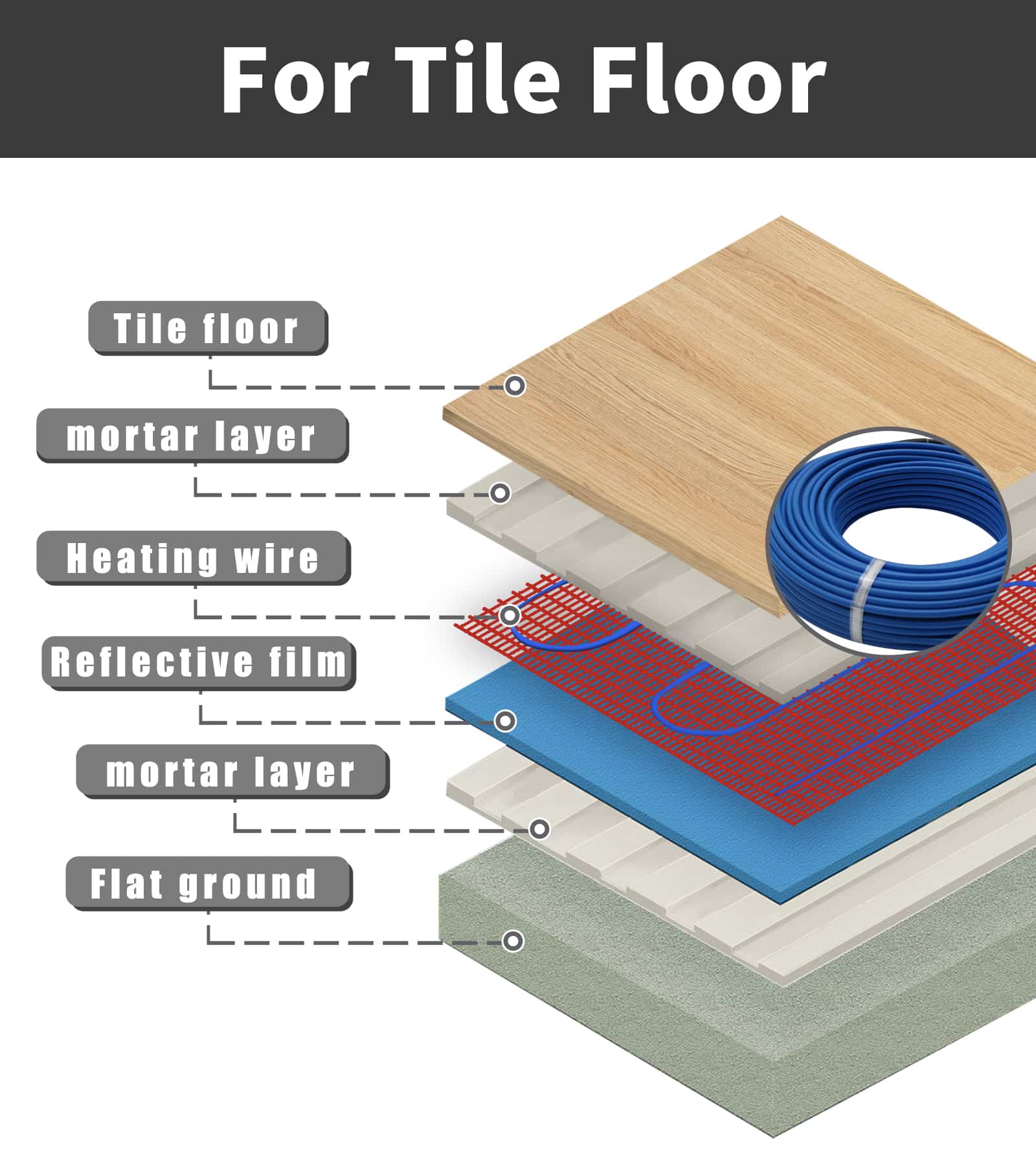

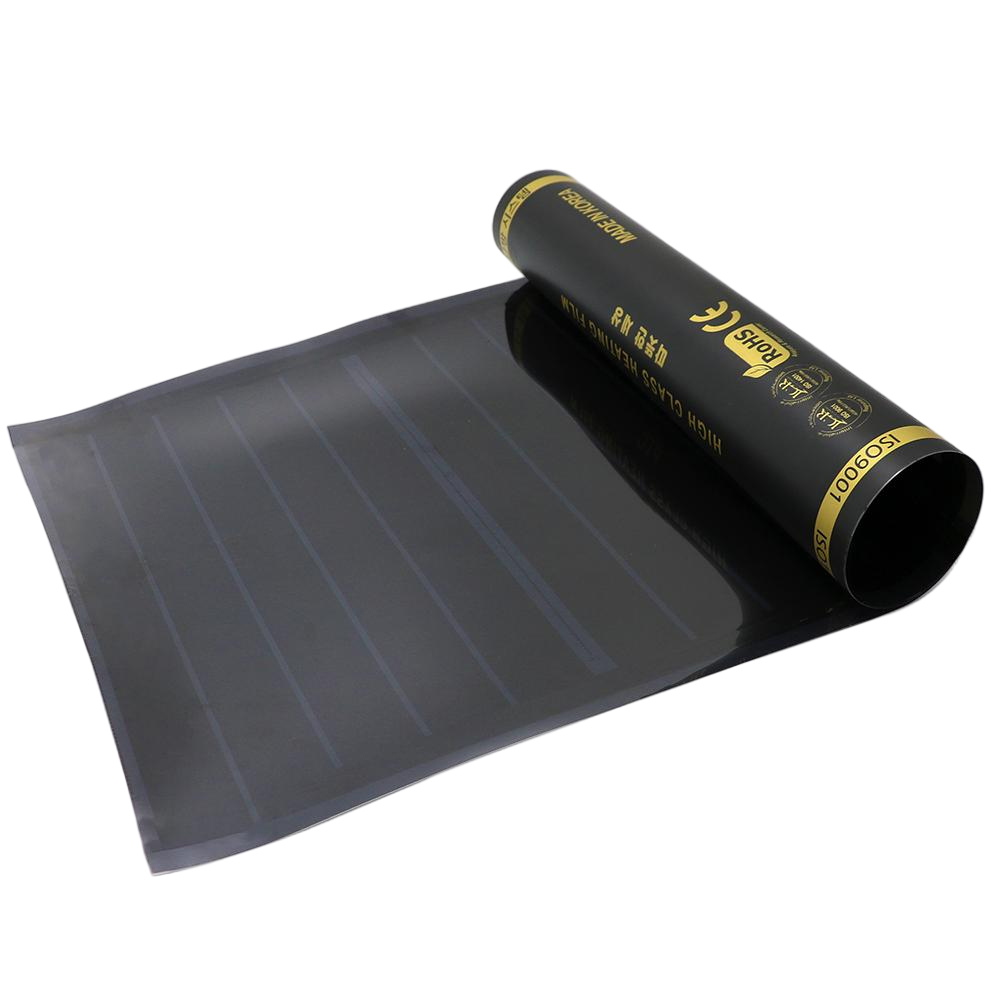

- Prohibit folding and heavy pressure: Avoid folding, rolling, or placing sharp objects on the heating mat to prevent the internal heating wire from breaking or the heating film from being damaged; Household mattresses should not be powered on when folded, while industrial equipment should ensure a tight fit with the surface of the equipment without any hanging or squeezing.

- Control usage duration and temperature: Control the duration of single use according to the instructions (recommended for household use not exceeding 8 hours, industrial use should not exceed 24 hours of continuous operation and should be stopped for heat dissipation), to avoid long-term high-temperature operation accelerating material aging; During sleep, it is necessary to set the temperature to low or activate the timer function to reduce the load on the heating element.

Clean after use

- Power off cooling: Before cleaning, the power plug must be unplugged and the hot seat must be completely cooled before operation to prevent high temperature burns or electric shock.

- Gentle cleaning: Use a wrung out damp cloth to wipe the surface dust. For stubborn stains, dip a small amount of neutral cleaner and gently wipe. Do not use strong acid or alkali cleaners to avoid corroding the surface material; After cleaning, it needs to be dried before storage or use, and should not be exposed to direct sunlight.

2、 Special maintenance for different scenarios

Home use scenario (mattress/sofa/bathroom heating mat)

Mattress style:

- Regularly remove the surface cover (if removable) for cleaning, and do not directly wash the heating seat body with water (only wipe it off); When storing, lay flat or roll into a cylinder with a diameter of ≥ 30cm, avoid folding, store in a dry and ventilated place, away from damp wardrobes or floors.

- Avoid using other heating devices such as electric blankets and hot water bags on the heating seat to prevent damage to the heating element caused by excessive local temperature.

Waterproof design for bathroom:

- After each use, dry the surface water and regularly check whether the IP waterproof sealing strip is aging and cracking. If it cracks, replace the sealing strip to ensure waterproof performance; The splash box of the power socket should be kept closed to prevent water vapor from entering the socket and causing a short circuit.

Industrial scenario (equipment insulation/pipeline heat tracing heating mat)

Equipment outer wall design:

- Regularly check whether the outer insulation layer has fallen off, and if it has fallen off, it should be promptly replenished to reduce heat loss while protecting the heating mat from industrial dust and oil pollution; Every six months, use a multimeter to check the resistance value of the heating seat. If the deviation from the factory value exceeds ± 10%, the machine should be stopped for maintenance to prevent uneven heating.

- The heating mat that comes into contact with chemical media should be checked quarterly for corrosion spots on the surface fluoroplastic sheath. If it is damaged, it should be replaced immediately to prevent the medium from penetrating into the interior and damaging the heating element.

Pipeline heating system:

- After the winter heating is stopped, it is necessary to clean the frost and impurities on the surface of the pipeline, check whether the fixing buckle of the underground heating seat is loose, reinforce it again, and do a good job of moisture-proof protection; Outdoor pipeline models need to be additionally wrapped with sunscreen and anti freezing protective sleeves to prevent low-temperature cracking in winter and UV aging in summer.

Agricultural scenario (greenhouse soil/seedling box heating mat)

Soil burial fee:

- After each season of planting, dig out the heating mat (avoid violent pulling), clean the soil and roots attached to the surface, rinse with clean water and air dry, check whether the PE waterproof film is damaged, and repair the damaged area with special waterproof glue; Keep away from corrosive materials such as pesticides and fertilizers during storage to prevent material aging.

Nursery box model:

- Regularly wipe the surface with alcohol swabs to disinfect and remove residual roots of seedlings; When storing, place it in a dry cardboard box to prevent rodents and insects from biting the power cord and surface material.

3、 Prevention and emergency response of common faults

Core measures for preventing malfunctions

- Avoid frequent plugging and unplugging of plugs to reduce poor contact and oxidation of plugs; Household models should not use inferior power strips, while industrial models should be equipped with leakage protectors.

- When not in use for a long time, the power should be unplugged, cleaned and dried before storage. Every 3 months, power on and run for 10 minutes (at low temperature) to activate the heating element and prevent internal components from becoming damp and ineffective.

Emergency response

- If there is any odor, smoke, or local overheating during use, immediately cut off the power, stop using, and contact professional after-sales service. It is strictly prohibited to disassemble on your own; If there is a slight leakage, it is necessary to check whether the socket grounding is normal. If there is no grounding, a grounding device should be installed.

4、 Maintenance taboos

- It is strictly prohibited to wash or soak the heating mat body with water, even for IPX7 waterproof models, it should not be soaked in water for a long time.

- It is strictly prohibited to pry or puncture the surface of the heating seat with sharp tools to avoid damaging the internal heating element and circuit.

- It is strictly prohibited to self wire or replace components when the heating seat malfunctions. Non professional operations may cause safety accidents such as electric shock and fire.